Insights

How to reduce complexity in the retail supply chain

Jonathan Colehower, Global Supply Chain Strategy Practice Lead

Supply chain visibility is a critical component of an efficient supply chain system

Jonathan Colehower, Global Supply Chain Strategy Practice Lead

Supply chains have faced a volatile period in the past months. While it seems the world is emerging from the worst of the pandemic crisis, its effects will linger for some time. Rapid digitalization and increasing complexity in supply chains have been challenging for enterprises.

Global enterprises need advanced technology to tackle these challenges and incorporate digital transformation into their supply chain management (SCM) strategies to stay competitive. Here are five ways technology reduces supply chain complexity and creates more resilient, productive, and strategic systems.

DIVIDER

Quick Takeaways

- Visibility is a critical component of efficient supply chain systems and can be enhanced using big data, Internet of Things (IoT), and Artificial Intelligence (AI) solutions.

- Modern technologies enable a holistic integration of demand planning strategies into supply chain operations, allowing better inventory tracking and insights.

- Supply chain risk management (SCRM) significantly reduces risk and increases the lead time for developing solutions to potential challenges.

- AI solutions help leverage predictive analytics since datasets are too large for human teams to manage and assess.

- Technology solutions across the supply chain help increase overall agility and scalability.

- 5 ways to reduce complexity in the retail supply chain.

DIVIDER

1 Supply chain visibility

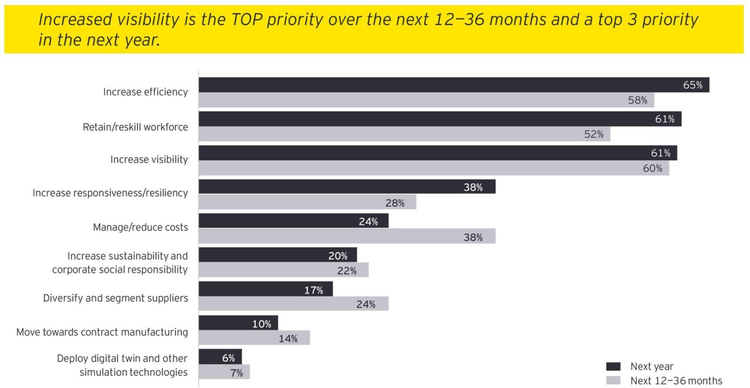

Supply chain visibility is a critical component of an efficient supply chain system. Recent research by Ernst & Young found that executives rate it as the top supply chain priority for the next 12-36 months and in the top three for the following year.

Complexity related to supply chain visibility can be reduced and streamlined with the right technology. These include:

- Big Data - Data insights can be used to perform real-time order fulfillment, track inventory, spot trends, and conduct objective KPI assessments.

- Internet of Things - IoT is making a great impact on visibility and inventory tracking. Technologies like QR codes, barcode scanners, motion sensors, and more provide real-time updates and allow for a unified view for everyone in the supply chain.

- AI-powered Analytics - Artificial Intelligence takes the big data from multiple areas and uses algorithms to turn it into predictive insights. AI can also be utilized to integrate with other systems in order to automate operations, shorten delivery time, optimize partner relationships, and drive innovation.

DIVIDER

2 Demand planning and promotion

Demand planning enables businesses to meet customer demands while eliminating excess inventory and avoiding supply chain disruptions. Demand planning leverages data insights about consumer trends, customer behavior, sales history, and productivity to meet customer demands with the highest possible accuracy.

Demand planning that is integrated into supply chain operations can lead to increased profitability, better efficiency, and higher customer satisfaction. It is a cross-functional process involving many moving parts. Advanced solutions offered by technology transformation companies can help streamline, track and manage these moving parts with demand planning software solutions.

Modern supply chain technologies transform demand planning from a reactive process (i.e., always playing catch-up to meet demand) to a strategic component of everyday operations. Once integrated into the SCM holistically, companies can make informed decisions and achieve accurate forecasting.

DIVIDER

3 Risk assessment

More companies now see how technology can enhance supply chain visibility and efficiency. But few realize its potential for minimizing risk. We have witnessed the volatility of supply chains during the pandemic and its impact on business processes and communities.

Risk and volatility are not new to supply chains. They have long faced natural disasters, cyber threats, and geopolitical issues. However, digitalization and globalization have increased the likelihood of these potential issues.

Companies need advanced technology to deal with these increasingly complex supply chain systems. They need to work with technology transformation companies to help identify issues in specific stages and implement quick solutions to manage those problems.

Supply chains face many risks related to inventory, procurement, and finances. Investing in supply chain risk management (SCRM) can significantly reduce this risk and increase the lead time to develop solutions and face unavoidable challenges like the ones we faced in the past 18 months.

When implemented using the right technologies and approaches, supply chain risk management can become a cyclical, integrated part of your overall supply chain management. Over time, this creates a more resilient supply chain that is better positioned to handle predictable and unexpected challenges.

DIVIDER

4 Predictive analytics

Modern supply chains collect and store vast amounts of data. Implementing predictive analytics strategies with AI and machine learning effectively harnesses that data and enhances supply chain efficiency.

As economies evolve rapidly and supply chains become more complex, predictive analytics will become more imperative for global enterprises.

DIVIDER

5 Agility and scalability

The result of implementing advanced supply chain technologies is the ability to operate with agility and scale up or down as demand requires.

The result of implementing advanced supply chain technologies is the ability to operate with agility and scale up or down as demand requires.

They can now get a unified view across the supply chain that enables better demand planning, risk assessment, and accurate forecasts using big data. Companies can operate supply chains without the rigidity and lag time that existed in the past.

DIVIDER

Access end-to-end supply chain solutions today

UST’s Omni™ solution combines the strengths and capabilities of UST and Gravity Supply Chain to provide an integrated end-to-end visibility and execution platform that is unparalleled in the market today.

Contact us today to learn more!